At Raymond, we push the envelope in technology and innovation to help our customers complete jobs more efficiently. Some of the technological innovations that we are using now are opening the door for building in a whole new way.

On current projects, AI powered tools capture 360° digital views of entire projects, flagging potential issues. Robotic layout tools take information directly from Raymond BIM models to automate the layout of floors, walls, soffits, door openings, and mechanical openings.

Electric fireproofing pumps are being utilized on projects. The machines have zero emissions, are quieter, more reliable, safer, and easier to transport.

Raymond continues to use prefabrication to save time, add value, and improve quality on our projects.

At Durango Stations in Las Vegas, Raymond prefabricated exterior panels offsite, helping to compress the schedule. Following framing fabrication and exterior sheathing, panels were delivered to the jobsite where an EIFS finish was applied on a vertical application utilizing assembled framed supports and a rolling scaffold system.

On a recent project with repetitive design features in Los Angeles, Raymond fabricated over 2000 shear walls and 500 trusses offsite, to be shipped flat and assembled as office pods on site.

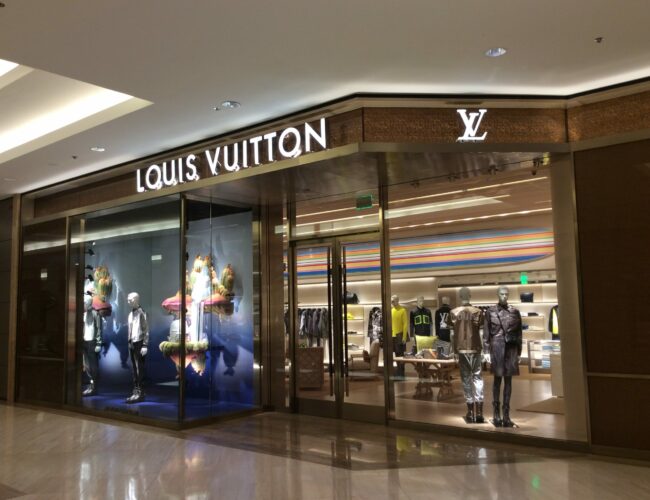

With all our innovations and Raymond’s quality, we are building unique and exciting projects — From high end build outs for architecture firms and high end tenant improvements, to 5-star entertainment venue suites.

We are ‘building the unbuildable’ and constantly performing work in the field that we hadn’t done before.

At Horton Plaza, a new tech hub in San Diego, Raymond installed a bamboo exterior finished wall, unique in its vertical installation in lieu of standard horizontal orientation. Although the fastening system is identical, the level of difficulty in the layout process was extreme, with fastening clips centered equally. The track system supporting the clips was imbedded into a direct applied plaster finish system leaving little or no room for error.

At 8th & Figueroa, a mixed-use development in Los Angeles, Raymond participated in the design and construction of an out-of-this-world Corian waterfall grand ornamental stair spanning two levels. The stair had a total of 32 treads with a Corian “fin” at each end. As the stair ascends step by step, the Corian lengthens or lessens with it, ending at each tread’s front with a curved element while continuing curved off the other end and extending through the ceiling above.

Months of coordination and onsite reviews pave the way for the realization of these unique projects. We look forward to future innovations, challenges overcome, and the ultimate success of our customers.